THE BASICS

Enerfit is a patented variable fan speed retrofit for single-zone commercial air conditioning units that substantially reduces the air conditioning electrical consumption and improves comfort by reducing the relative humidity.

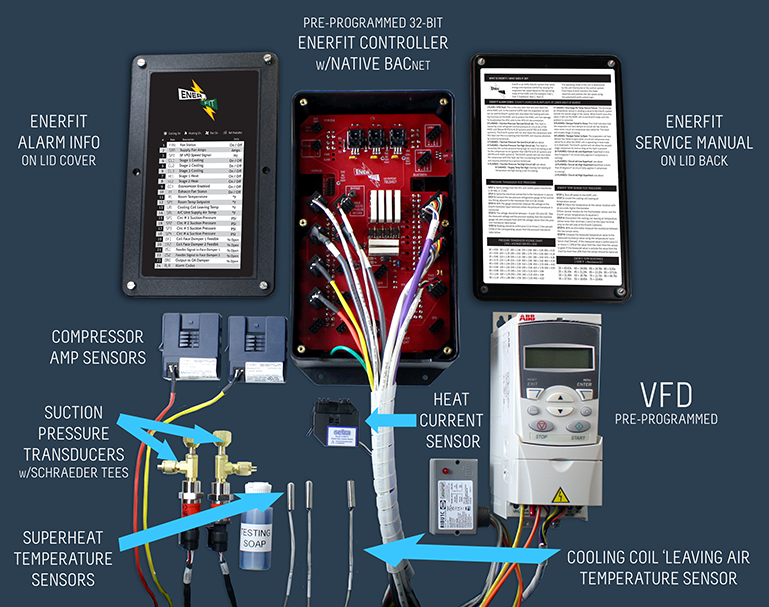

To achieve such significant savings, Enerfit uses a VFD (Variable Frequency Drive) to control the speed of the evaporator (indoor) fan motor, a powerful controller and a set of precision sensors.

Variable speed fan control for single-zone air conditioning units has been an industry accepted energy saving HVAC system for over 30 years when used with chilled water systems — the system is called single-zone variable air volume (SZVAV).

SZVAV has not been used to any degree on direct-expansion (DX) cooling systems used on packaged rooftop air conditioning units. Packaged rooftop air condition units are used on 60% of all commercial buildings in the United States.

The reason SZVAV has not been applied to DX systems is due to operational problems that occur when varying the airflow across a DX cooling coil. The primary problems associated with this approach have been coil icing and severe compressor damage.

Enerfit’s patented methodology and hardware solves the problems associated with variable airflow across DX coils and provides similar savings to the chilled water SZVAV systems. No other retrofit on the market modulates the indoor fan in the cooling mode to provide a constant temperature supply air at any time the HVAC unit is in mechanical cooling mode.

Enerfit significantly reduces the evaporator fan energy consumption in the heating, ventilation, and economizer modes as well.

To achieve such significant savings, Enerfit uses a VFD (Variable Frequency Drive) to control the speed of the evaporator (indoor) fan motor, a powerful controller and a set of precision sensors.

Variable speed fan control for single-zone air conditioning units has been an industry accepted energy saving HVAC system for over 30 years when used with chilled water systems — the system is called single-zone variable air volume (SZVAV).

SZVAV has not been used to any degree on direct-expansion (DX) cooling systems used on packaged rooftop air conditioning units. Packaged rooftop air condition units are used on 60% of all commercial buildings in the United States.

The reason SZVAV has not been applied to DX systems is due to operational problems that occur when varying the airflow across a DX cooling coil. The primary problems associated with this approach have been coil icing and severe compressor damage.

Enerfit’s patented methodology and hardware solves the problems associated with variable airflow across DX coils and provides similar savings to the chilled water SZVAV systems. No other retrofit on the market modulates the indoor fan in the cooling mode to provide a constant temperature supply air at any time the HVAC unit is in mechanical cooling mode.

Enerfit significantly reduces the evaporator fan energy consumption in the heating, ventilation, and economizer modes as well.

Single-zone rooftop units with three-phase indoor fan motors (approximately six tons or greater) are prime candidates for the Enerfit retrofit. The results of Enerfit’s technology are reduced annual HVAC electrical consumption (50% or greater) and reduced relative humidity in the conditioned space (10-20% RH).

Enerfit’s technology, although unique, is strictly based on sound engineering principles, some of which were developed in the early 1900s by the inventor of modern air conditioning, Willis Carrier. The engineering principles developed by Mr. Carrier have been the cornerstone of air conditioning theory since then and are still valid today.

The use of fan speed retrofits such as Enerfit is gaining traction. The DOE (US Dept. of Energy), ASHRAE (American Society of Heating, Refrigeration & Air Conditioning Engineers) and RILA (Real Estate Industry Leaders Association) are sponsoring a program to promote the use of this technology by retrofitting existing units and incorporating it into new units.

WHAT MAKES ENERFIT DIFFERENT FROM OTHER RETROFIT OPTIONS?

The primary difference between Enerfit and other single-zone RTU offerings is Enerfit’s cooling mode methodology.

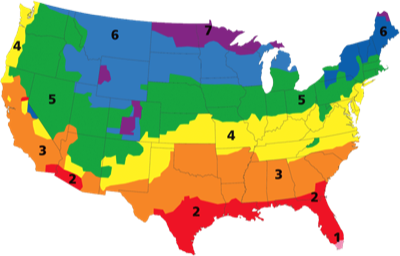

The cooling mode is by far the most important of the operating modes because in most commercial buildings, internal heat gains dictate that the HVAC will operate in cooling mode about 50% of the time in Climate Zones 5 through 7 and 60%-70% of the time in Climate Zones 1 through 4. (See climate map below)

The cooling mode is by far the most important of the operating modes because in most commercial buildings, internal heat gains dictate that the HVAC will operate in cooling mode about 50% of the time in Climate Zones 5 through 7 and 60%-70% of the time in Climate Zones 1 through 4. (See climate map below)

Enerfit’s cooling methodology allows the fan speed to be significantly, but safely, reduced during part load cooling and, in most cases, during full load cooling. The resulting savings come for two sources.

The first (and more obvious) source is the fan energy savings that are achieved as a result of reducing the fan speed. It is widely known in the HVAC industry that the evaporator fan energy is reduced per the Affinity Law #3 which says that the fan energy is reduced as the cube of the fan speed reduction.

The first (and more obvious) source is the fan energy savings that are achieved as a result of reducing the fan speed. It is widely known in the HVAC industry that the evaporator fan energy is reduced per the Affinity Law #3 which says that the fan energy is reduced as the cube of the fan speed reduction.

The second source (which is less obvious) is the reduced fan heat that is delivered to the space by the evaporator fan. The fan heat is also reduced by the Affinity Law #3.

The reduction of fan heat reduces the cooling load in the conditioned space and therefore reduces the compressor and condenser fan energy required to offset the fan heat.

A secondary difference, but nevertheless and important difference between Enerfit and other retrofit offerings is that Enerfit provides proactive trouble-shooting information and alarms.

This information can alert the service technician of an impending problem and also greatly assist the service technician with troubleshooting.

The reduction of fan heat reduces the cooling load in the conditioned space and therefore reduces the compressor and condenser fan energy required to offset the fan heat.

A secondary difference, but nevertheless and important difference between Enerfit and other retrofit offerings is that Enerfit provides proactive trouble-shooting information and alarms.

This information can alert the service technician of an impending problem and also greatly assist the service technician with troubleshooting.

THE PROBLEMS

The large majority of commercial single-zone HVAC units are oversized. This happens for several reasons: compounding safety factors, liability concerns if the unit is undersized and unknown future cooling requirements. Also, thanks to cost-effective lighting and demand controlled ventilation retrofits, many building have reduced their original cooling load as well.

That is the situation where most building owners find themselves - their units are understandably oversized, but they are stuck with the problems that oversizing causes. In addition to wasting energy, oversized units have a very negative impact on occupant comfort.

As tonnage is oversized, airflow follows along proportionally. The end result is building systems that are significantly "over-aired". Often this causes the space to be noisy and drafty during the spring, fall, and winter.

In warm and humid climates, however, this is the least of the comfort problem. Units that are “Over-Aired” will consistently cause high relative humidity problems in the conditioned space resulting in occupant discomfort and possible mold and mildew growth.

It is an accepted fact in the air conditioning industry, that lowering the relative humidity allows for the implementation of higher temperature setpoints without compromising occupant comfort. The ability to raise cooling temperature setpoints is yet another unique way that Enerfit saves both fan and compressor energy.

That is the situation where most building owners find themselves - their units are understandably oversized, but they are stuck with the problems that oversizing causes. In addition to wasting energy, oversized units have a very negative impact on occupant comfort.

As tonnage is oversized, airflow follows along proportionally. The end result is building systems that are significantly "over-aired". Often this causes the space to be noisy and drafty during the spring, fall, and winter.

In warm and humid climates, however, this is the least of the comfort problem. Units that are “Over-Aired” will consistently cause high relative humidity problems in the conditioned space resulting in occupant discomfort and possible mold and mildew growth.

It is an accepted fact in the air conditioning industry, that lowering the relative humidity allows for the implementation of higher temperature setpoints without compromising occupant comfort. The ability to raise cooling temperature setpoints is yet another unique way that Enerfit saves both fan and compressor energy.

ENERFIT ADDS PROTECTION FOR RTUS

Single zone RTUs built in the last 15 years have had marginal protection on both the electrical and refrigerant sides of the units.

Enerfit does not interfere with ANY of the RTU manufacturer's electrical or refrigerant safeties on the RTUs.

On the electrical side, Enerfit adds significant protection, not just for the indoor fan, but for the compressors and condenser fans as well. Fault conditions such as phase failure, phase reversal and ground faults are just a few of the critical safeties that are included when an Enerfit retrofit is installed. Although any one of these faults can cause significant damage to the RTUs, none of these safeties currently exist on most existing RTUs.

On the refrigerant side, Enerfit provides proactive alarms not currently available on most existing RTUs. By monitoring the refrigerant system, Enerfit can notify the end user and/or service technician that the RTU is using more energy than it should even though it appears to be running normally. This early warning system prevents excessive loss of refrigerant, costly shutdowns, occupant discomfort and - most importantly - wasted energy.

Enerfit does not interfere with ANY of the RTU manufacturer's electrical or refrigerant safeties on the RTUs.

On the electrical side, Enerfit adds significant protection, not just for the indoor fan, but for the compressors and condenser fans as well. Fault conditions such as phase failure, phase reversal and ground faults are just a few of the critical safeties that are included when an Enerfit retrofit is installed. Although any one of these faults can cause significant damage to the RTUs, none of these safeties currently exist on most existing RTUs.

On the refrigerant side, Enerfit provides proactive alarms not currently available on most existing RTUs. By monitoring the refrigerant system, Enerfit can notify the end user and/or service technician that the RTU is using more energy than it should even though it appears to be running normally. This early warning system prevents excessive loss of refrigerant, costly shutdowns, occupant discomfort and - most importantly - wasted energy.